50L Fixed Type Vacuum Emulsifier Mixer Paste Lotion Making Machine SUS Material

Datos del producto:

| Lugar de origen: | China |

| Nombre de la marca: | LIANHE |

| Certificación: | CE , ISO , SGS , TUV |

| Número de modelo: | LH-VME-F50 |

Pago y Envío Términos:

| Cantidad de orden mínima: | 1 |

|---|---|

| Precio: | negotiable |

| Detalles de empaquetado: | Empaquetado de la película de la caja/de la burbuja de la madera contrachapada |

| Tiempo de entrega: | 30 días laborables |

| Condiciones de pago: | T/T, L/C, D/A |

| Capacidad de la fuente: | 20 sistemas por mes |

|

Información detallada |

|||

| Capacidad de diseño: | 63L | capacidad de trabajo: | 50L |

|---|---|---|---|

| Capacidad disponible: | 5L-6000L | Velocidad de mezcla: | 0-65rpm |

| Velocidad del homogeneizador: | 0-3600rpm | Sistema de calefacción: | Calefacción eléctrica/calefacción de vapor |

| Sistema del vacío: | -0.1MPa | Material: | SUS316L/SUS304/SUS304 (3 capas) |

| Estructura del tanque: | El tanque principal + el tanque de agua + el tanque de aceite | ||

Descripción de producto

50L Fixed Type Vacuum Emulsifier Mixer Paste Lotion Making Machine

Brief Introduction:

- The vacuum emulsifiers produced by our company include many varieties. The homogenizing systems include top homogenizer, bottom homogenizer, internal and external circulating homogenizer. The mixing systems include single-way mixing, two-way mixing and helical ribbon mixing. The lifting systems include single -cylinder lifting and double-cylinder lifting. Various high quality products can be customized according to customer's requirements.

- The triple mixing adopts the imported frequency converter for speed adjusment, which can meet different technological demands.

- The homogenizing structure made through German technology adopts the improted double-end mechanical seal effect. The maximum emulsifying rotation speed can reach 4,200rpm and highest shearing fineness can reach 0.2-5μm.

- The vacuum defoaming can make the materials meet the requirement of being aseptic. The vacuum material sucking is adopted, and especially for the powder materials, vacuum sucking can avoid powder floating.

- The emulsifying pot lid can adopt lifting system, easy to clean and the cleaning effect is more abvious, the emulsifying pot can adopt tilt discharge.

- The pot body is welded by imported three-layer stainless steel plate. The tank body and pipes adopt mirror polishing, which fully meet the international standards.

- All material contact parts are made of SUS316L, which can meet the manufacturing standard of cosmetic, pharmaceutical and food industries.

![]()

Technical Parameter:

| Capacity (L) | Homogenizer | Agitator | Vacuum pump | Heating system | ||||

| power (kw) | speed (rpm) | power (kw) | speed (rpm) | power (kw) | Limit vacuum | Electric heating (kw) | Steam heating (Mpa) | |

| 5 | 0.55 | 0-3600 | 0.4 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 10 | 1.1 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 20 | 1.5 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 9 | 0.2 |

| 50 | 3 | 0-3600 | 0.75 | 0-65 | 0.75 | -0.1 | 12 | 0.2 |

| 100 | 4 | 0-3600 | 1.5 | 0-65 | 1.5 | -0.1 | 24 | 0.2 |

| 200 | 5.5 | 0-3600 | 1.5 | 0-65 | 2.2 | -0.1 | 28 | 0.2 |

| 300 | 7.5 | 0-3600 | 3 | 0-65 | 2.2 | -0.1 | 32 | 0.2 |

| 500 | 11 | 0-3600 | 4 | 0-65 | 4 | -0.1 | 50 | 0.2 |

| 1000 | 15 | 0-3600 | 5.5 | 0-65 | 4 | -0.1 | 54 | 0.2 |

| 2000 | 18.5 | 0-3600 | 7.5 | 0-65 | 5.5 | -0.1 | recommend steam heating | 0.2 |

| 5000 | 22.5 | 0-3600 | 15 | 0-65 | 7.5 | -0.1 | 0.2 | |

| The parameters are for reference only, all the machines can be customized according to your needs. |

||||||||

Application Product:

This machine is suitable for cosmetic cream, paste, mayonnaise, shampoo, syrup, etc products in cosmetic, food, beverage, chemical, daily chemical, beverage, pharmaceutical, medical, etc industries. If customers have any doubt on the machine, or if you are not sure whether this machine is suitable for your products or not, please send us inquiry and we will get back to you very soon.

![]()

Main Features:

- Complex scraping board blending oar is suitable to every kind of complicated recipe and achieve optimizing effect;

- Polytetrafluroethylene scraping board cater to body of blending groove and scrape out viscosity material on boiler wall;

- Homogenizer is installed on boiler bottom to increase motor power more thoroughly and strongly. During few production, it can exert homogenizing effect fully;

- Mightiness balance isotactic curve rotor is matched with stator with corresponding structure to realize liquid high -capability cut,rubbing,centrifugal to make sure exquisite and slick cream; boiler body and pipe surface mirror polishing 300EMSH (sanitation grade) accords with Daily Chemical and GMP regulation.

- Homogenizing vacuum emulsifier mixer can choose frequency conversion timing homogenizer and highest rotate speed is 3600 r/min.

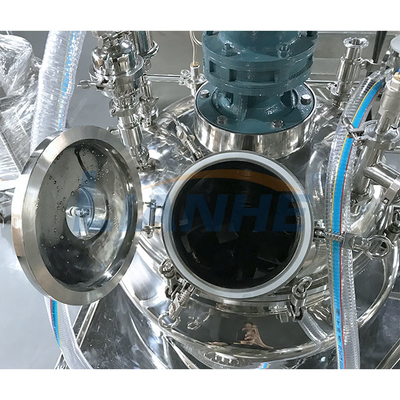

Machine Details:

![]()

![]()

![]()

Customer's Reviews:

![]()

Exhibition & Project Cases:

![]()

S